|

Model |

YSCD65*75 |

YSCD65*100 |

YSCD75*100 |

|

Power(kw) |

55/75*2 |

90/110*2 |

110/132*2 |

|

Capacity(t/h) |

4-5 |

5-8 |

6-10 |

|

Hammer(pcs) |

114 |

192 |

192 |

|

Weight(t) |

4.3 |

5.2 |

8.2 |

1.The wood hammer mill will be passed by the dynamic balance testing, the error of hammers is within 0.2g, which can guarantee the machine runs stably.

2.The materials of hammers is tungsten carbide spot welding. The hammers of hammer mill is thick; the effect is better.

3.Siemens Motor. It is frequency and has thick copper coil, it won’t be burned due to instantaneous current.

4.Feed inlet of wood hammer mill with anti-caulking baffle to prevent material collapse

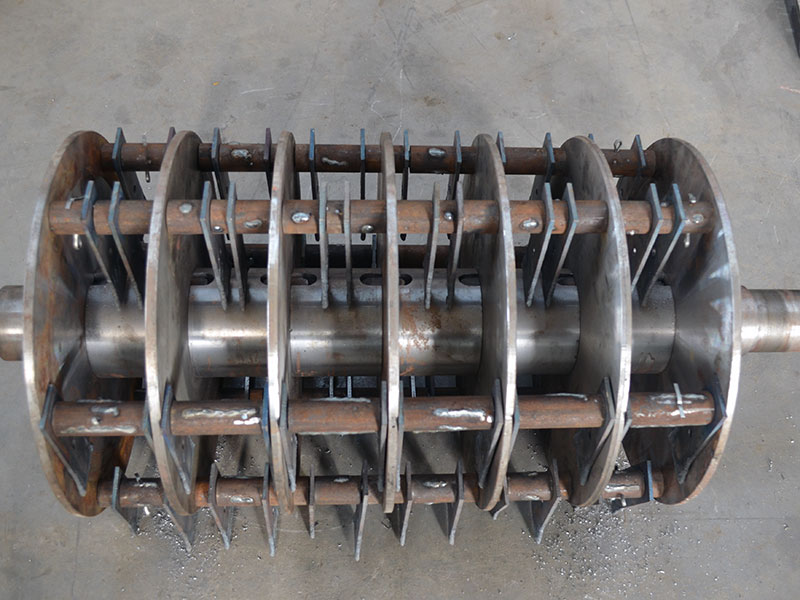

Rotor and hammer:

|

|

Raw material:

|

|

|

|

|

|

|

Chips |

Rice husk |

Shaving |

Straw |

Branch |

5.Motor of drum wood chipper use Siemens Brand. This kind of motor is frequency and has thick copper coil, it won’t be burned due to instantaneous current when entering long wood log.

6.The wood crusher machine will be passed by the dynamic balance testing, the error of hammers is within 0.2g, which can guarantee the machine runs stably.

7.Bearing block of wood crusher is made of bearing steel. The bearing block is big and wide, which makes sure that the hammer mill run stably.

8.The materials of hammers is tungsten carbide spot welding. The hammers of hammer mill is thick; the effect is better.

9.Feed inlet of wood hammer mill with anti-caulking baffle to prevent material collapse.

Hammer and screen:

|

|

Name: Christine

Mobile:+86-155 0868 1778

Tel:+86-0531-83658366

Email:info@rotexmaster.com

Add:Zhangqiu City,Shandong Province,China